Proylac Extrusion / Aluminios Galisur Booth No.: B01

Website: https://proylac.com/

Products:

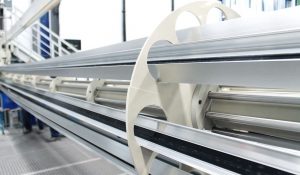

Extrusion, lacquering, anodizing, sublimation, precision cutting and machining

Company introduction :

Proylac Extrusion is consolidated as a clear example of innovation, sustainability and business growth.

More than 40 years ago, in 1978 Aluminios Galisur was born in Seville with the aim of offering a good distribution service of aluminum profiles and accessories for the aluminum carpentry sector. Since its inception, Aluminios Galisur has laid the foundations of the company it is today, experiencing gradual but continuous growth. This has led the company to go from being a distributor to dealing with the entire production process of manufacturing aluminum profiles for construction. In this sense, a few years after its foundation, the brand began an expansion process focused on the treatment and lacquering of aluminum under the name of Proylac Extrusion. This expansion has provided the company with a greater variety of finishes with the consequent reduction in delivery times.

The Sevillian company is committed to 100% recyclable and environmentally sustainable raw materials, even having its own recycling plant. The company has the ISO 14001 certification that guarantees responsibility with the environment.

More than 40 years driving innovation

From its Innovation and Development Center, Galisur develops the study and execution of all its projects. Through the direct contact that the company maintains with the needs of the market in the different stages through which the demand passes, the technical department follows a continuous innovation that agrees with the constant business vision of expanding the services offered to its clients together with the improvement of production processes, achieving added value.

The company has two aluminum treatment and lacquering plants, one of them horizontal and the other vertical, the latter being one of the most important in the sector nationwide. They have a wood finishing plant with two production lines that allows them to give their products a warm look through wood. In addition, its profile assembly plant allows them to optimize thermal insulation in areas with extreme weather, which is known in the industry as thermal break.

Proylac Extrusion covers the entire manufacturing process of aluminum profiles for construction, including the design and extrusion of aluminum profiles of all types and characteristics, storage of aluminum carpentry and accessories, and aluminum recycling. “Through aluminum extrusion we can manufacture a wide range of aluminum profiles that will be used in door and window carpentry for construction and design,” they point out from the company, which works with a wide variety of color and various types of imitation wood to meet the needs of its most demanding customers.

All this complying with the regulations of the European Union in relation to quality and service, required in the new technical building code (CE marking) for acoustic insulation, sealing and ventilation. “The certification of all our series is tested by laboratories notified and independent from the company, which avoids the arbitrariness of carrying out tests on our own carpentry, thereby obtaining greater veracity to the characteristics of our products”, they explain.

With 280 employees, the company can boast of having a highly qualified team in continuous training to always offer the most up-to-date solutions. Among its values we can highlight the continuous improvement of the conditions of its employees and the fight for equal